YOU DESIGNED A BETTER MOUSE TRAP

Your machinery fills a market need and is in high demand. You have engineering sign-off on the design and an approved budget. Now, you need the manufacturing ability to build and implement.

YOU COULD BUILD IT YOURSELF

Hire and train staff, develop manufacturing capabilities, and outline quality programs to support production. Sounds easy enough, but the process to ramp-up in house production takes time and resources and dilutes your effectiveness. Plus, your hands are full of marketing, sales, distribution, and customer service.

WHAT YOU REALLY NEED IS A RELIABLE BUILD PARTNER

AMD&E is a partner you can trust. We have decades of experience that you can immediately add to your team. Put our precision engineering, machine build, test, verification, and run-off skills to work to build your machine, speed up your customer delivery, drive your sales, improve your ROI, and increase your profits.

"Having a production partner like Accelerated has allowed us to put our focus on product development and marketing. Knowing that our equipment is going to be built right has been a major relief. This allows us to put our focus where it is needed and keep our overhead low."

– CEO of Construction Equipment company

NOW YOU CAN FOCUS ON GROWING YOUR BUSINESS

With AMD&E fulfilling your machine build requirements, you can stay focused on your business. Best of all, AMD&E always protects your intellectual property. We can private-label your machine, and build it according to your branding, markings, and serial numbers.

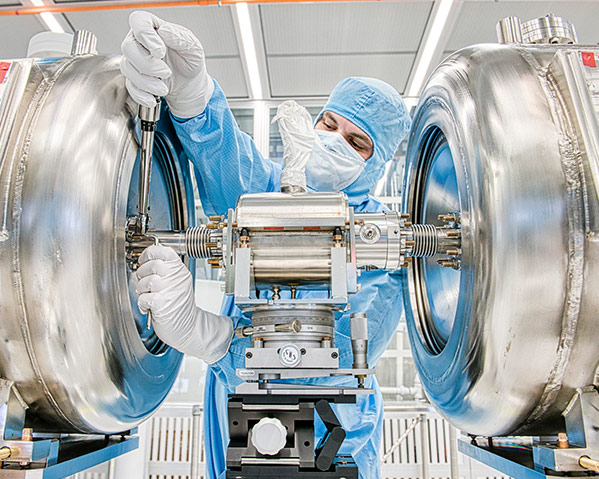

MACHINE BUILD SHOWCASE

MACHINE BUILD CAPABILITIES

Machine Builds

- Complete build to print

- Mechanical build only

Fixture, Gauge, or Tool Builds

- Sub-system and sub-assembly

- Wire, piping, and labeling

- Test & runoff

- Serialization and documentation

System Builds

- Electromechanical

- Hydraulic systems

- Electrical systems

Electrical Cabinets and Panels

- MEP services

High Volume Builds

- Assembly line builds

- Inventory & stocking of components

- Testing, documentation, and compliance

- Certifications (UL, CE, TUV, etc.)

THE AMD&E CHECKLIST GUIDES YOU SEAMLESSLY THROUGH THE MACHINE/BUILD PROCESS.

The Machine Build Process

Design Review

- Architecture & Design

- Determine Materials & Costs

- Review Procedures & Delivery Schedule

- Establish Factory Acceptance Test (FAT)

Proposal

- Submit Proposal & Cost Estimate

- Review Technical Plans with Client

- Answer Questions

- Discuss Options

Kickoff

- Prepare Purchase Order & Plan

- Team Kick-off Meeting

- Determine Objectives, Deliverables & Standards

- Establish Schedule

Procurement

- Confirm Bill of Material & Release to Production

- Order Raw Material & Components

- Perform Quality Control

- Assemble Kit Materials

Manufacturing

- Manufacture Components

- Perform Fabrication & CNC Machining

- Apply Paint & Coating if Applicable

- Inspect Components

Build

- Assemble Machine per Specifications

- Inspect Alignment & Geometry

- Performance Testing

- Document Serial Number

Factory Acceptance Test

- Factory Acceptance Test

- Document Performance Results

- Determine Performance Baseline for Machine

- Apply Certification Label

Deliver

- Properly Package Machine

- Numerically Label Packages

- Prepare Wood Crates to ISPM-15 Standards

- Ship

Markets We Serve

Space, Aerospace, Defense, Military

Energy

Clean Water, Food & Beverage

Biotech, Life Sciences, Agri Science

Healthcare Equipment

Agriculture, Off-Highway & Automotive Machinery

General Manufacturing & Industry

Precision Machinery Industry