WHEN IT'S TIME TO MODERNIZE

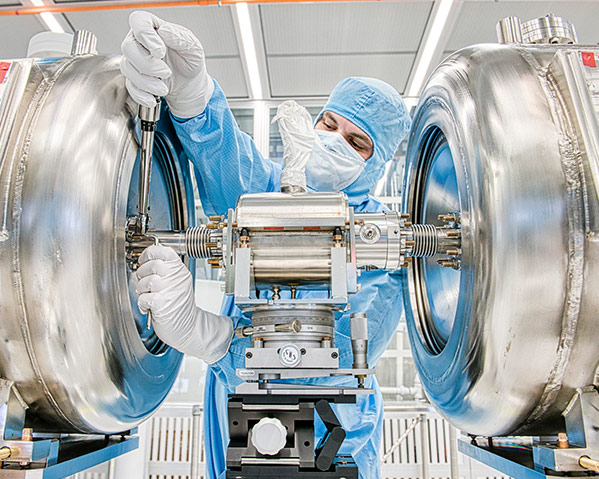

Rebuilding your vintage equipment with the very best in modern technology is often the best way to instantly realize efficiency and productivity gains.

SAVE TIME AND MONEY

AMD&E engineers will solve your quality and reliability problems by completely transforming your vintage iron with brand new machine components, controls and electrification to deliver a modern. state-of-the-art solution that will substantially increase your uptime and ROl for decades to come.

RENEWING MAY BE YOUR BEST OPTION

Plus, by renewing your existing machinery you'll save the cost of new equipment along with the steep learning curve that goes along with it. Your operators will be able to instantly increase productivity because they're using a modernized version of the machine they're already familiar with.

"I have been a supplier, and have worked for suppliers, in the industrial automation industry for over 10 years and I have rarely encountered somebodv with as much attention to customer satisfaction as Accelerated" - Engineer, Grundfos

THE CHOICE IS YOURS

So if rebuilding is the path you choose you really have two options: A standard rebuild, which gives you a new paint job, along with the same outdated technology, maintenance and reliability challenges you currently face. Or have AMD&E transform your vintage iron into a totally modern and reliable solution, customized to our exact needs.

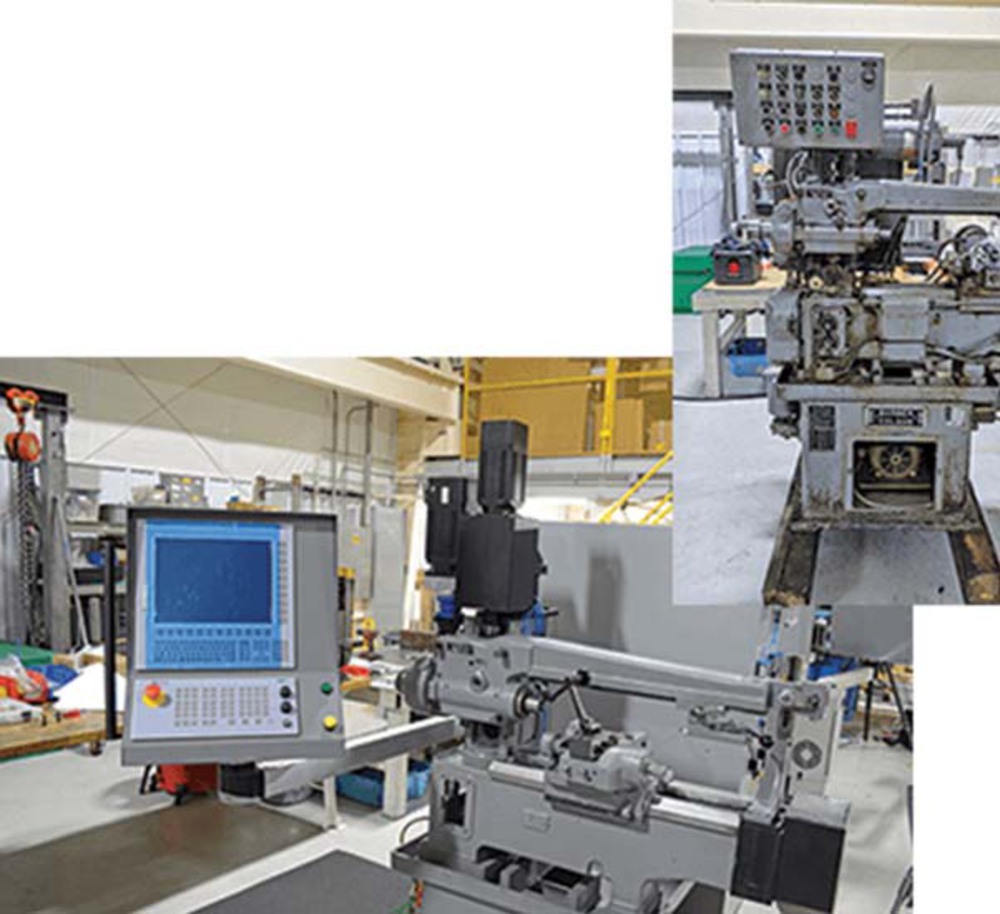

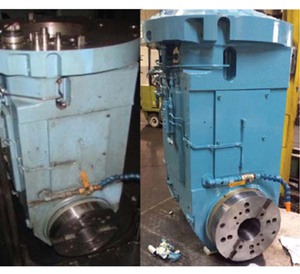

REBUILD SHOWCASE

Rebuild Services

Machine Rebuilds

- Complete rebuilds

- Machine upgrades

- New functionality

- Machine electrification

- Refurbish and repurpose

Spindle Rebuilds

- Rebuild, re-gear

- Refurbish

- Repurpose

- Electrification

Fixture Rebuilds

- Replace wear components

- Geometry certification

- Hydraulic clamp rebuilds

- Automation upgrades

Tool Changer Rebuilds

- Replace grippers

- Bearing and seal replacements

- Drive system updates

- Automation upgrades

Control System Upgrades

- Control system replacement

- Motor & drive upgrades

- HMI upgrades

- Custom HMI screens

- Camera integration

- Custom automation integration

- SCADA and factory automation integration

How To Get Started

To get started simply submit a picture or description of your machine today for a quote or to schedule a consultation with one of our rebuild experts.

The AMD&E Checklist

The AMD&E checklist guides you seamlessly through the rebuilding process.

Evaluation

- 360° assessment

- Evaluation report with pictures and summary findings

- Rebuild plan, itemized with costs and lead times

- Customer review

- Agreement & authorization to proceed

Restoration

- Teardown & methodical cleaning

- Refurbishment & restoration

- Seal & bearing replacement

- Rebuild & replace worn or damaged components

- New paint & coatings

Upgrade & Automation

- Drive train upgrades

- Lubrication automation

- Control system upgrades

- HMI upgrades

- Sensor installation

- Safety Integration

Performance Evaluation

- Alignment & geometry certification

- Systems checkout

- Calibration

- Run-in & stress test

- Factory acceptance test

Installation & Training

- Delivery

- Installation

- Training

- Site acceptance test

360° Support

Our long term support includes preventative maintenance, spare parts, field service, future upgrades and add-ons to ensure your system remains state of the art, and in top condition.

Markets We Serve

Space, Aerospace, Defense, Military

Energy

Clean Water, Food & Beverage

Biotech, Life Sciences, Agri Science

Healthcare Equipment

Agriculture, Off-Highway & Automotive Machinery

General Manufacturing & Industry

Precision Machinery Industry