We can guide you through the complexities associated with hardware and software integration, validation, and regulatory compliance testing that can seem overwhelming.

At AMD&E, we understand the rigors of testing and verification to meet program demands. Our services are tailored to meet the specific demands of each project, and our staff is qualified and trained specifically for each test activity we undertake for our customer. All results are documented to satisfy customer requirements as well as all applicable regulatory and governmental requirements.

Our test and verification service saves our customer time and monev, and provides comprehensive, understandable results that will satisfy compliance needs or help with ongoing product development.

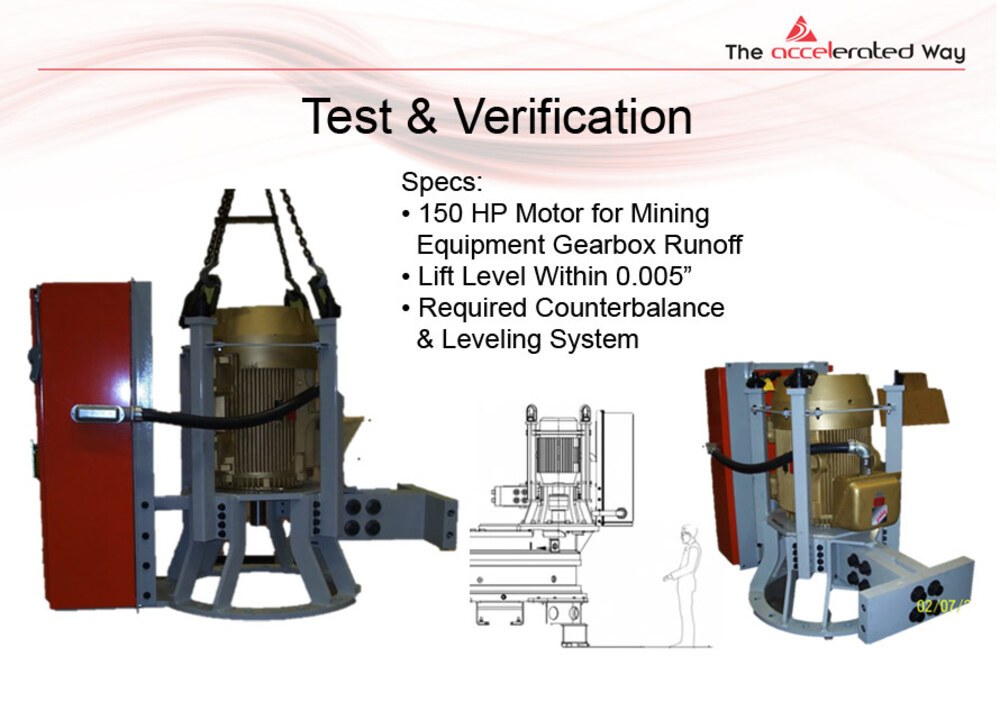

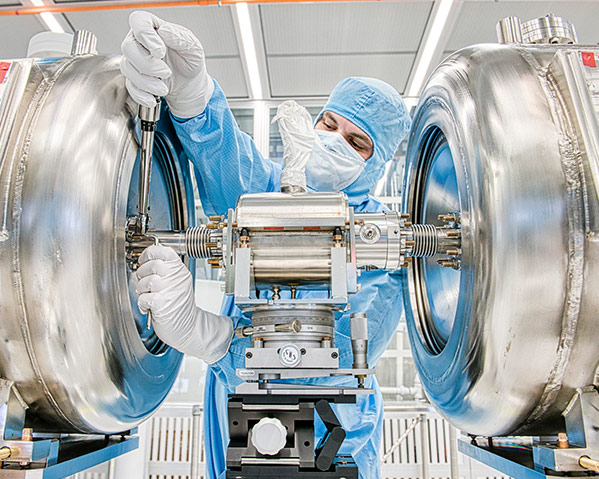

TEST AND VERIFICATION SHOWCASE

TEST & VERIFICATION CAPABILITIES

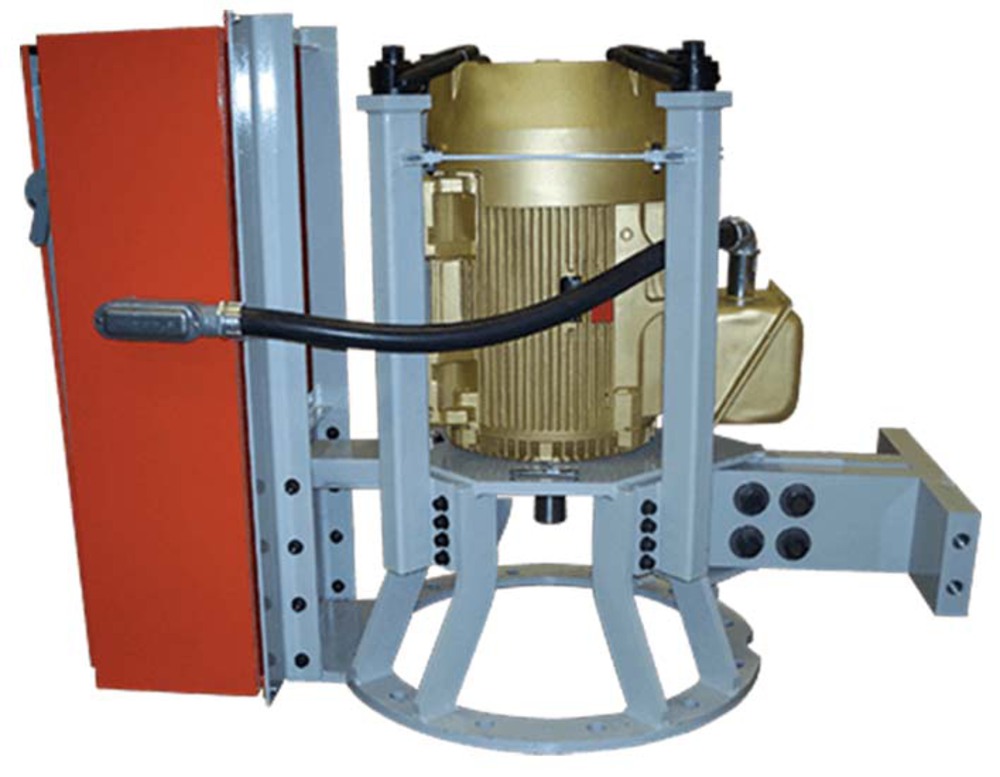

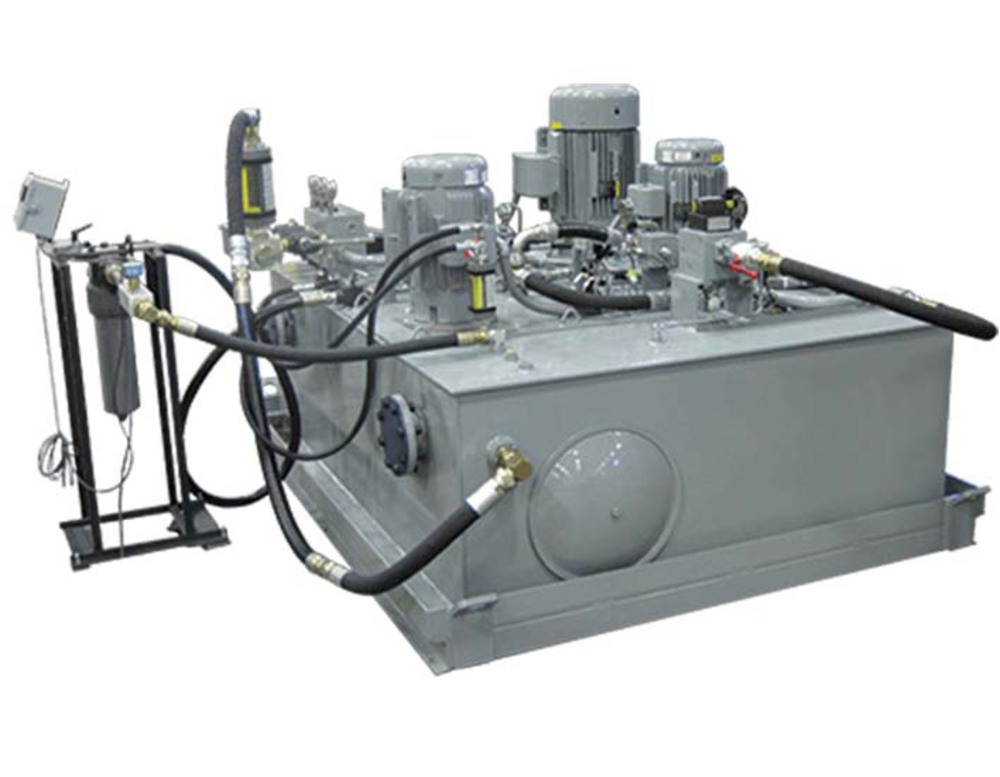

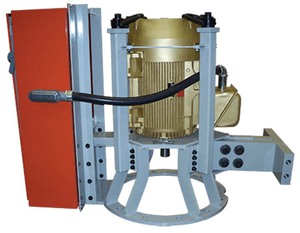

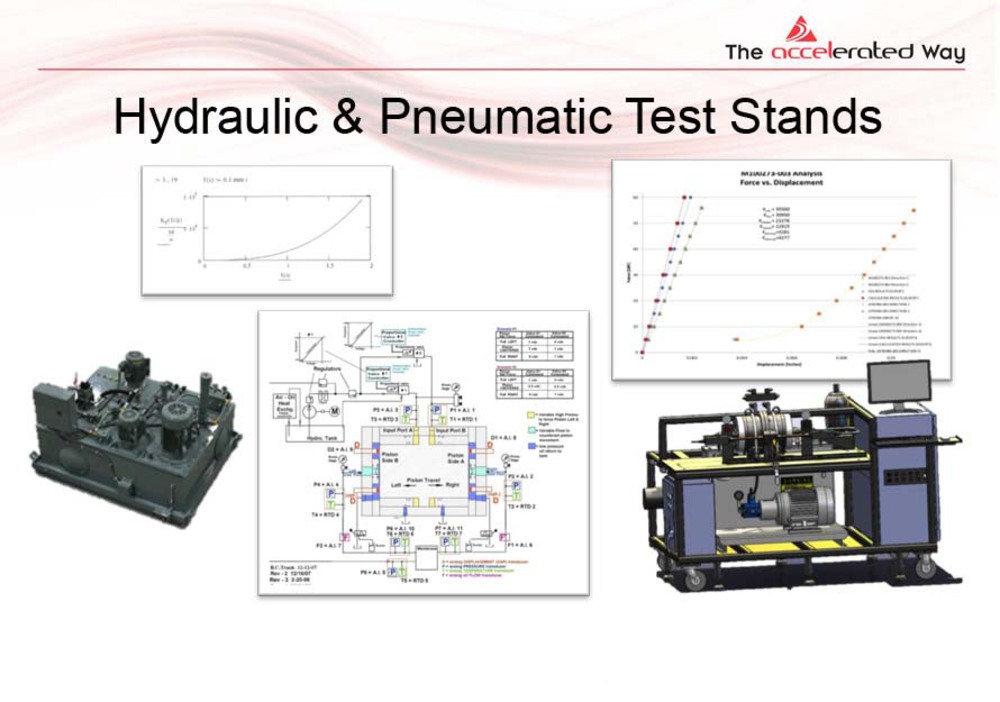

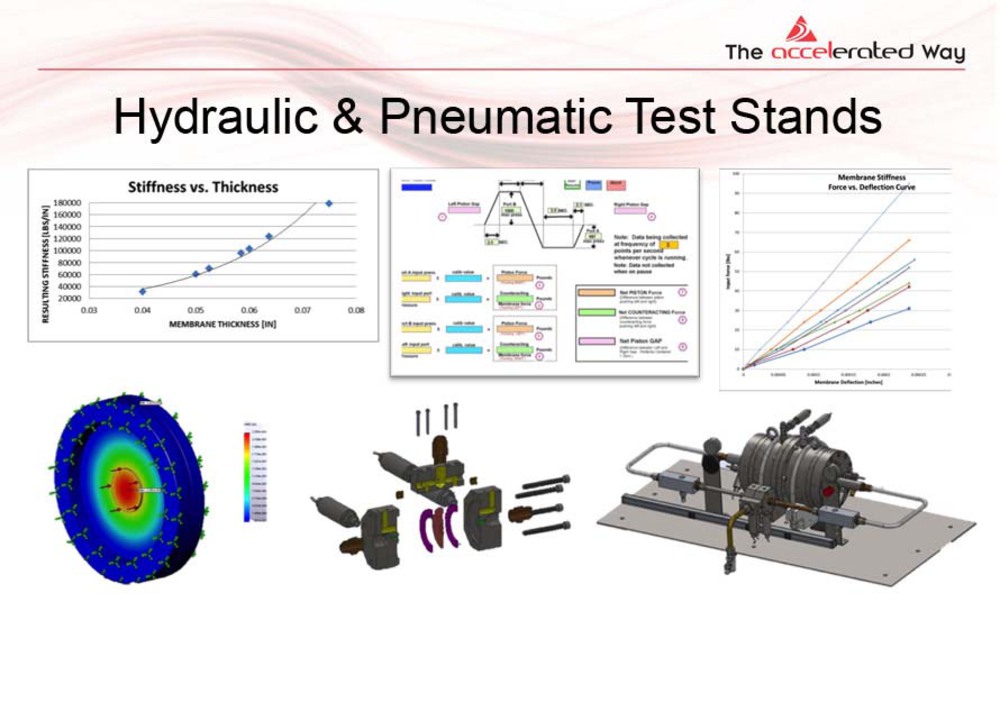

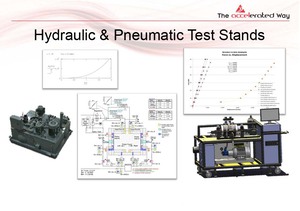

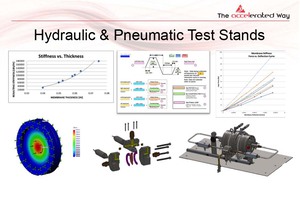

Test Stand Development

- Mechanical, electrical, oneumatic, hydraulic, thermal & acoustic test svstems

- Test stands for aerospace, medical, automotive & defense manufacturing industries

- Calibration stations

- Component manufacturing verification and assembly verification stations

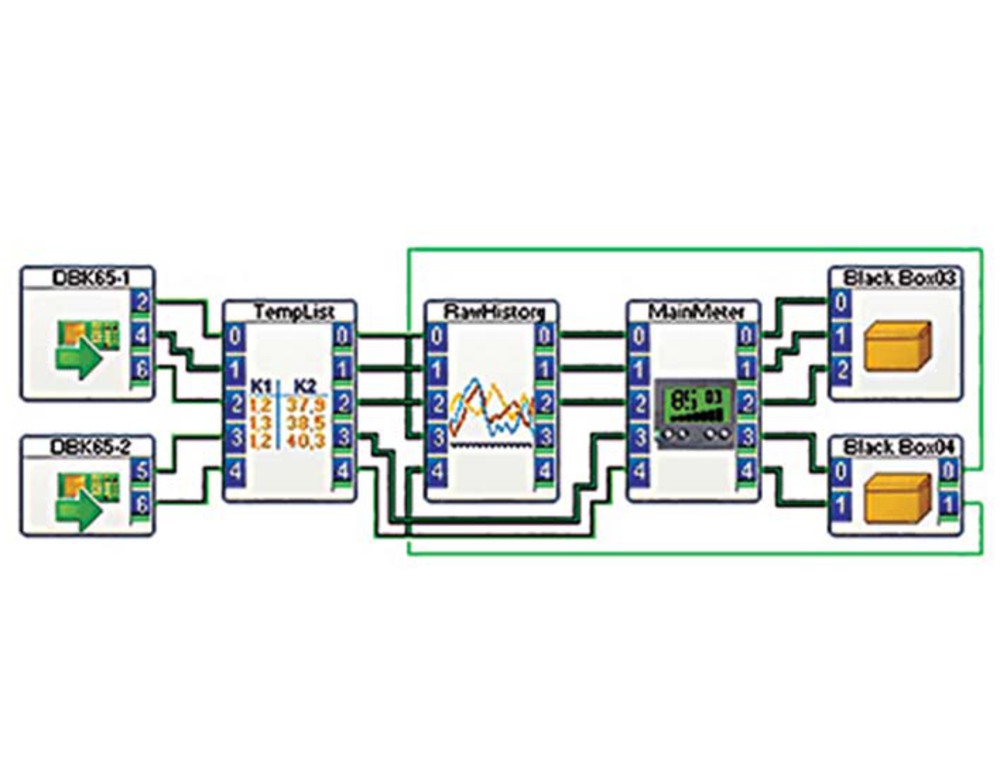

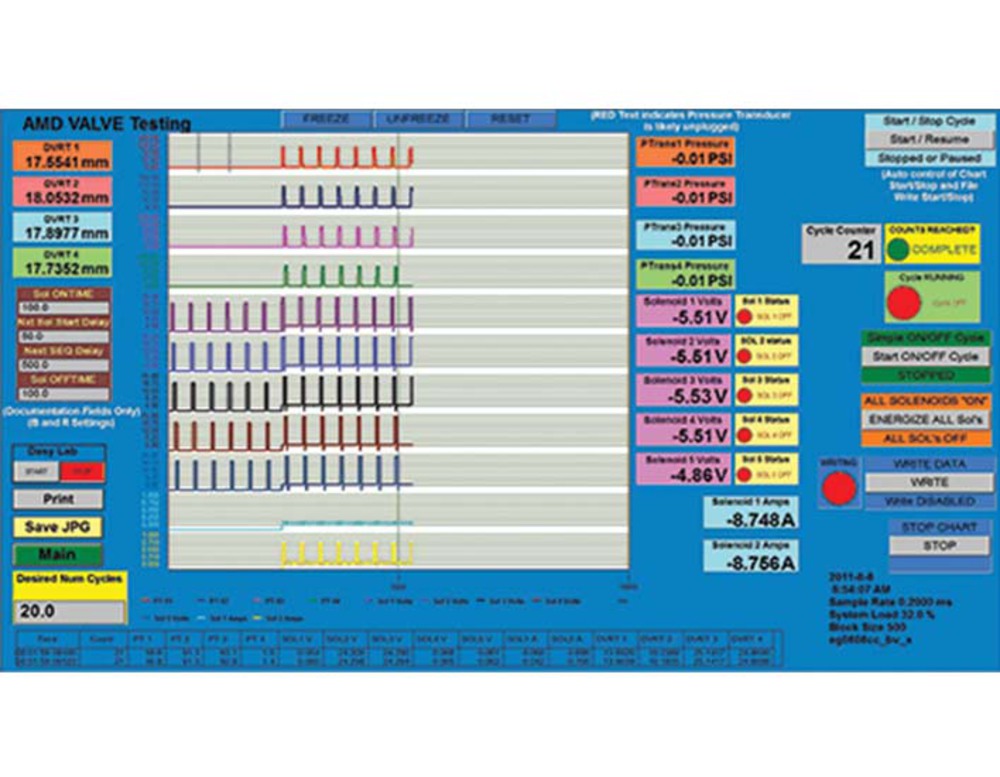

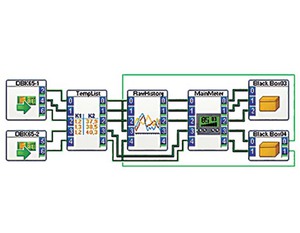

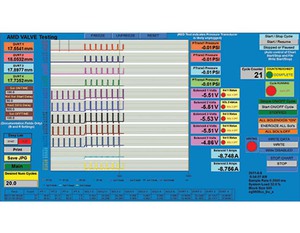

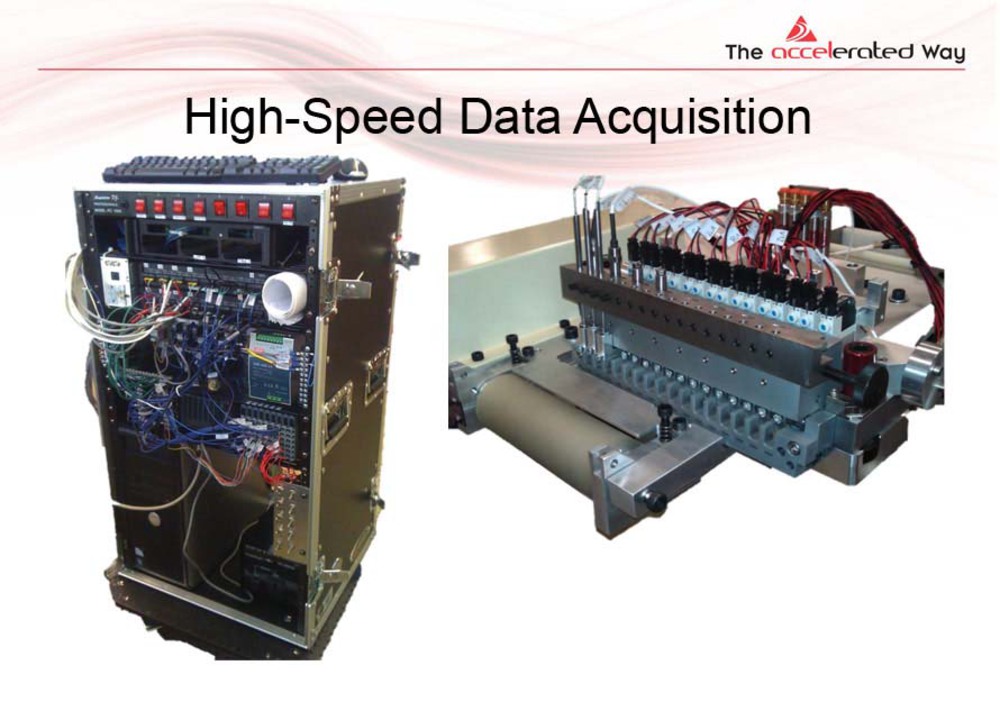

- Measurement computing hardware and software development, including LabVIEW

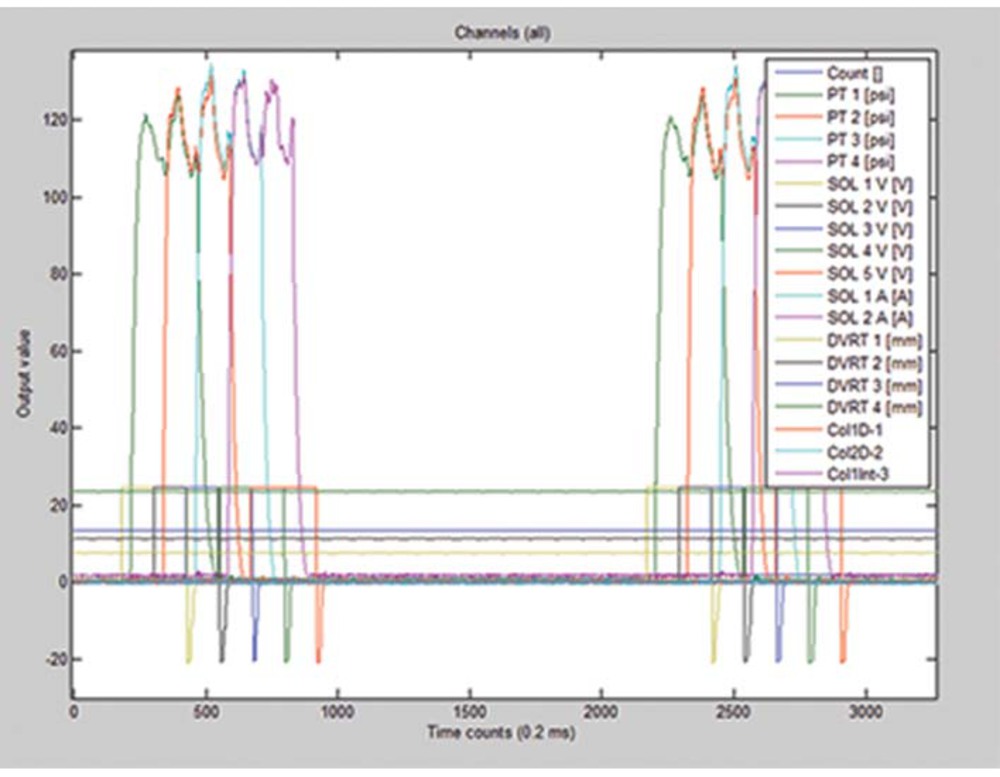

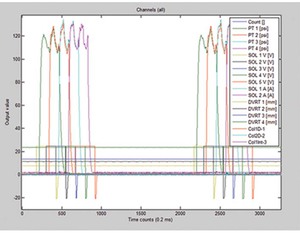

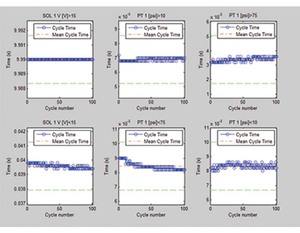

- In-process, real-time, remote data collection and analysis capability

- Post-processing, analysis, and reporting

Electrical Testing

- Specification compliance (design verification) and performance verification

- Analog and digital signal testing

- PCB testing, hardware testing, harness & cable testing

- Test equipment verification

- Performance verification to agency standards

Software Testing

- Feature testing

- Emulation

- Static, dynamic, white box, black box, grey box, regression, etc.

Mechanical Testing

- Mechanical property testing: hardness, displacement, stress, strain, elongation, compression, fatigue, and impact to ASTM standards

- Material property testing: composition, corrosion

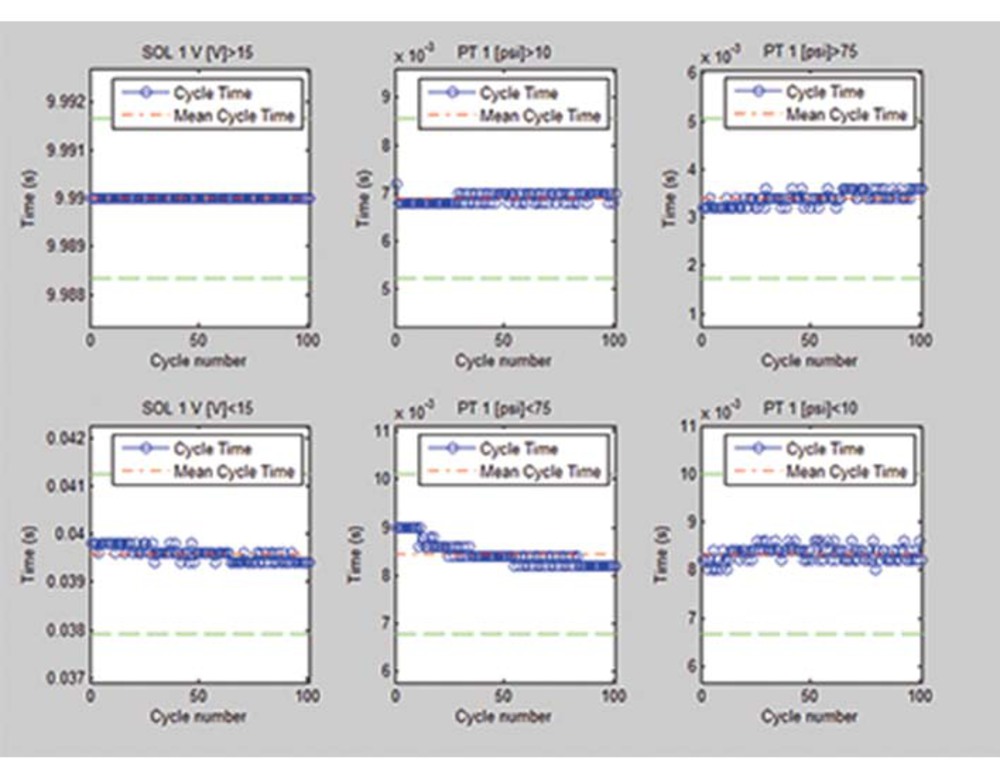

- Mechanical system testina: pressure, displacement, vibration, acceleration, velocitv, torque, etc.

- Dynamic system performance evaluation

- Modular, reconfigurable, high-frequencv multi-channel DAQ in-house test stand for rapid data collection

Non-Destructive Testing

- Modal response & vibration characterization

- X-Ray inspection, magnetic particle inspection, fluorescent penetrant inspection

- Dimensional & geometric inspection

Geometric Inspection

- Dimensional and geometric part inspection to ASME Y14.5vstandards for geometric dimension and tolerances for individual component and assemblies

- Optical inspection: micro & macro

- CMM, measuring arm, laser tracker

- Laser & white light scanning

TEST & VERIFICATION ASSETS

Markets We Serve

Space, Aerospace, Defense, Military

Energy

Clean Water, Food & Beverage

Biotech, Life Sciences, Agri Science

Healthcare Equipment

Agriculture, Off-Highway & Automotive Machinery

General Manufacturing & Industry

Precision Machinery Industry